Quiet life is best for military vehicles

Tom Lee, Senior Engineer at MIRA, explains how military personnel can be protected from noise and vibration while on patrol in their specialist vehicles

By applying cutting edge Noise, Vibration and Harshness (NVH) engineering techniques that have been refined through 30 years of NVH development in the automotive industry, NVH engineers have been able to significantly improve the NVH characteristics of military vehicles destined for use in some of the world’s toughest environments.

Legislation aimed at limiting personnel exposure to excessive levels of noise and vibration in the workplace has meant that all military vehicles must meet strict health and safety guidelines, before they can be passed for safe use in the field. Military vehicles face a number of unique NVH challenges in theatre including the need for heavily armoured vehicles carrying troops and heavy equipment to quickly travel over rough terrain. This has meant that NVH engineering for the military has become a complicated task, but by applying clever engineering design with proving ground testing and NVH simulation software packages, companies such as MIRA have been able to meet these tough requirements.

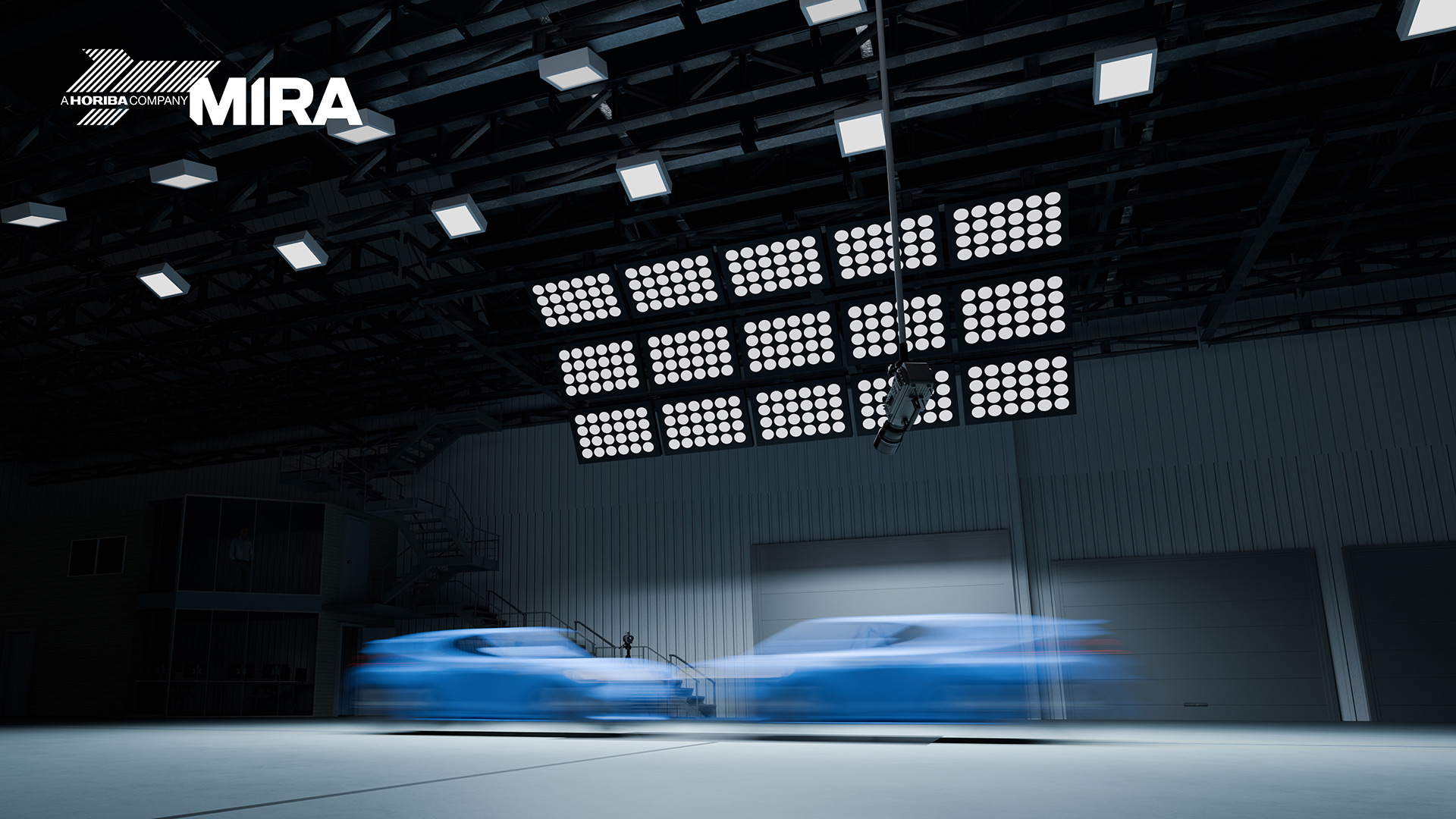

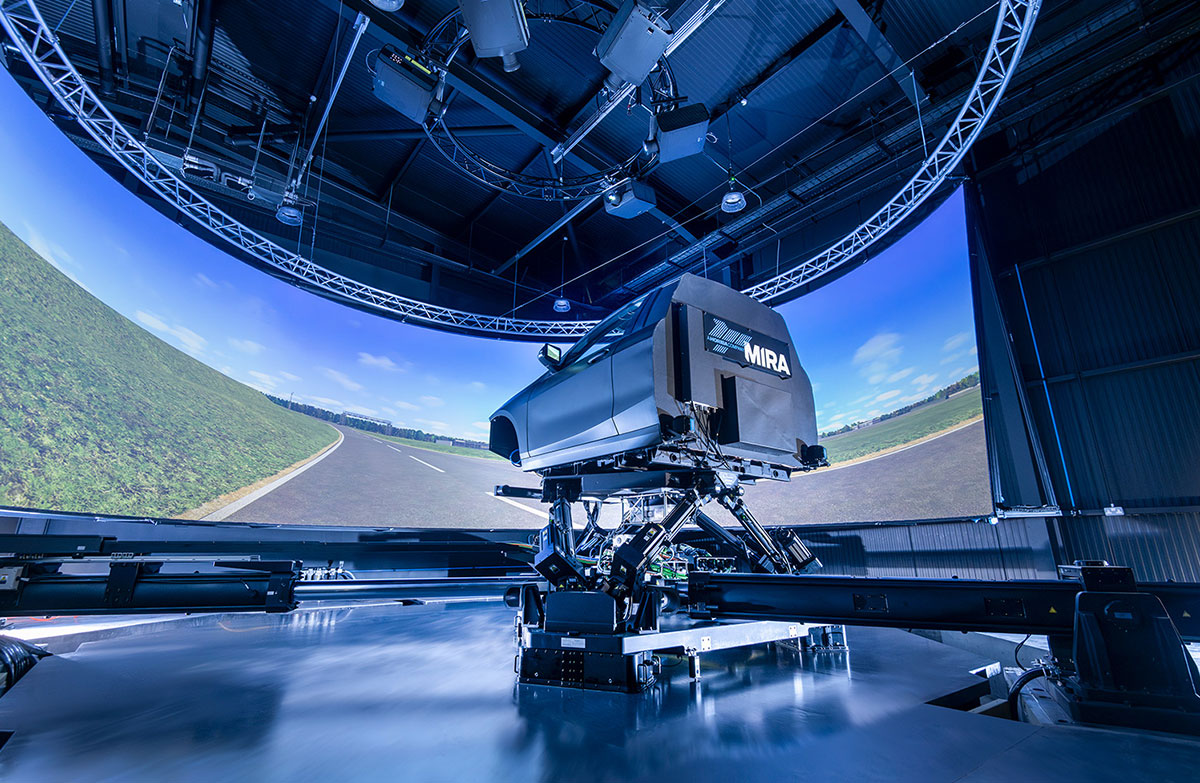

One of the tools available to NVH engineers is the use of dedicated test facilities such as the pavé, rough road, cross-country track and smooth road surfaces at MIRA’s proving ground, as these are perfect for simulating some of the harsh terrain that military vehicles will encounter in the field. NVH engineers will often put new suspension systems and components through their paces on these specialist surfaces to enhance vehicle performance whilst maintaining user comfort. MIRA also has the advantage of a virtual proving ground where each of these surfaces is mapped for virtual development. CAD and CAE packages are employed by specialists in order to design novel new suspension systems, for seats inside the vehicles, which are capable of withstanding structure borne vibrations whilst they are laden with troops carrying heavy equipment such as weapon systems and body armour. These design changes can be tested and proven on the virtual proving ground prior to manufacturing new parts for real world testing.

Specific ergonomic requirements also have to be taken into account by NVH engineers when developing seating systems for military vehicles, as troops wearing body armour and ruck sacks are not able to sit comfortably in a normal seating position in standard seating. By developing ergonomic seats with a removable section, NVH engineers at MIRA have been able to solve this problem and ensure that personnel are sat in the correct position during transit.

The combination of all these advanced engineering solutions has enabled MIRA to greatly improve the NVH performance of a wide variety of world leading military vehicles on the front line. In some cases the exposure limit of vehicles has been increased by a factor of ten, with troops now able to safely operate inside the vehicles for hours rather than minutes. By reducing exposure to excess levels of vibration and noise, personnel are able to concentrate for longer, are less fatigued when they go into battle and are less likely to suffer medical conditions in later life such as vibration white finger. In support of this MIRA was keen to produce a tool for end users that would give them the exposure information that they required in a simple manor that was easily displayed. MIRA developed a noise and vibration exposure calculator, which enabled defence customers to effectively plan and mitigate against potential exposure levels during missions. The calculator allows users to input the different traveling requirements of a vehicle and specify how long will be spent on each type of surface. The calculator will then assist the user in planning their mission and the required breaks to ensure that the occupants are not exposed to excessive levels of vibration.

NVH engineering also plays an important part in military vehicles carrying ordnance, as consideration has to be taken into account for limiting exposure to vibration. Measurements can be taken on the vehicle to map the structure borne vibration content throughout the vehicle. This can enable a source path contribution to be performed that will allow the engineers to analyse the contribution from each noise source through the structure. By combining this information with CAE development, engineers at MIRA can ensure that ordnance components and personnel are not exposed to levels of vibration that may affect their operation.

MIRA will be exhibiting at the Eurosatory defence and security exhibition in Paris from 16-20 June. If you would like to discuss NVH engineering with our experts please visit us on stand number C250 – Hall 6.