Aerodynamics experts at MIRA have developed a unique design for box trailers that, alongside subtle aero enhancements to the cab, reduces total drag by up to 30 per cent whilst retaining its practicality in operation.

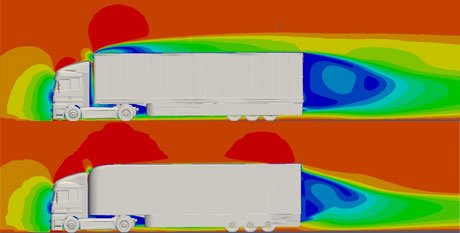

Interpreting data gathered using the latest Computational Fluid Dynamics simulation techniques, MIRA applied its expertise to improving the poor aerodynamic performance of a standard 4.5m box trailer – seeking to preserve its load capacity but reduce drag to the levels of a smaller 4m equivalent.

Dr Anthony Baxendale, Senior Manager for Advanced Engineering at MIRA, said:

“From the outset we wanted to design a solution that recognised the operational considerations of business but still deliver tangible performance gains in financial and environmental terms.

“We used CAD geometry and ‘morphing’ techniques to modify the trailer shape and maximise aerodynamic efficiency without compromising overall load space. We then added underbody panels to the cab and trailer to further minimise drag – the result of which was a reduction of up to 30% whilst avoiding the complex surfacing and space constraints of ‘tear drop’ designs.”

MIRA’s aerodynamicists calculate that the resulting fuel savings and reduction in CO2 emissions (of between 15 and 20 per cent) mean the cost of the adaptations to the trailer could be recouped by fleet operators within 12 months. The enhancements can also be applied to curtain-sided trailers – making it highly commercially viable and highlighting why MIRA’s design was recognised with an award from by the Low Carbon Vehicle Partnership in November.

MIRA’s efforts to retain practicality when redesigning the 4.5m trailer saw the rear door aperture reduced only marginally, to the height of a standard 4m box trailer, for ease of loading and underbody panels enable easy access for routine maintenance on brakes and axles and apertures were created in the side skirts to allow for checking of the wheel nuts.

Performance measures used during the project included levels of yaw, which enabled MIRA to effectively manage the crosswind behaviour of the trailer – with the final design achieving a reduction in both lift and sideforce that also improves stability. The wake sizes at both straight ahead and under yaw conditions have also been significantly reduced, which will reduce the amount of spray generated by the design on wet roads.

MIRA’s expertise in optimising aerodynamics for the haulage industry includes the creation of the original Truck Aerodynamic Styling Good Practice Guide, as well as numerous projects around the world for truck manufacturers including DAF, Leyland and Hyundai. It is now in discussion with a number of potential commercial partners interested in its aerodynamic design.