Data Driven Calibration Optimisation – DDCO

The drive for ever more efficient and zero-carbon mobility solutions is bringing a corresponding level of increased complexity within the vehicle systems.

- This is coming at a time when markets are demanding faster product time to market and for lower overall costs

- This could be achieved by using fewer expensive prototypes and/or by optimising the overall energy/efficiency of the whole vehicle system

- To meet this challenge, a holistic, whole system approach is needed, that provides a robust, data driven optimisation of system level calibration

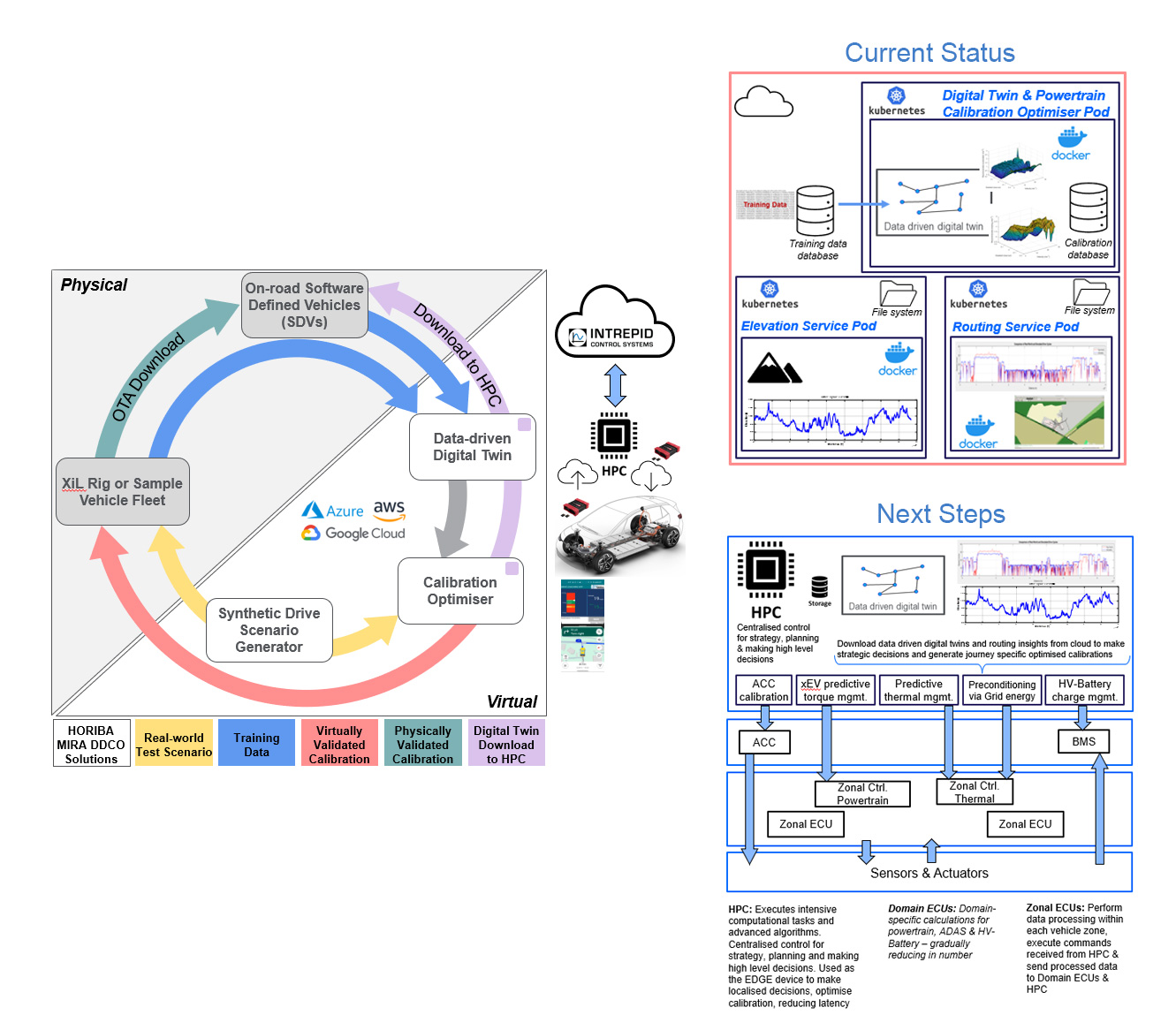

- Data Driven Calibration Optimisation (DDCO) is an advanced methodology that delivers optimised net zero solutions in an efficient manner, using a combination of emulation and physical UUT on XiL rigs, chassis dyno, proving ground or via PoC fleet vehicles

- This family of innovative solutions, hosted in a virtual or cloud environment, can be linked in real time with the UUT under test on a XiL rig

- These solutions provide a test eco-system that allows offline testing & calibration optimisation at both sub-system and system level

- The tools can generate representative real-world drive cycles, enabling control strategy testing, development & calibration to a high fidelity

- The machine learning (ML) algorithms have been developed to receive real-time training data from the UUT, generating digital twins in a virtual environment that are used for high accuracy performance prediction

- The calibration optimisers for HV-Battery BMS and torque management further reduce the engineering effort associated with achieving optimal calibration focusing on maximising system level energy efficiency needed, that provides a robust, data driven optimisation of system level calibration

OUR PARTNERS

Intrepid Control Systems are leaders in Vehicle Networking Interface Solutions, with over 30 years of expertise influencing the future of automotive network technology. Their commitment of excellence is reflected in their state-of-the-art hardware and software tools, designed to meet the evolving needs of OEMs and Tier ones suppliers.

Their product portfolio encompasses a wide range of applications, including:

- Vehicle Network Interfaces

- Data Logging & Cloud Analysis

- Simulation & Bench Testing (SIL, HIL & VIL)

- Gateways & Prototyping

Intrepid Control Systems application tools are designed to streamline the development process, from the initial Network connectivity to finding the issues in early detection and early resolution activities add core value where their customers need it most. This ensures that customers can bring safer and more sophisticated vehicles to market faster. Whether it’s through providing advanced diagnostic capabilities, facilitating seamless data integration, or enabling robust simulation environments, Intrepid’s solutions are tailored to support the complex demands of modern vehicle development of ‘Software-Defined Vehicles‘ SDV.

To find out more get in touch with our engineering teams [email protected] or visit https://intrepidcs.com

Intrepid’s application experience and flexible product ecosystem provides the ideal backbone for the Data Driven Calibration Optimisation (DDCO) concept, Intrepid were able to support with network interfacing hardware to capture the relevant and complex vehicle data, which is then sent to their cloud environment which hosts the DDCO models and analytical data to ensure the models have the correct data. Finally, once the optimisation has been completed the hardware devices are able to provide Over-The-Air (OTA) software updates capability, effectively closing the loop in the entire system and delivering continuous improvement.

Intrepid’s Data Logging and Cloud Analysis solutions are utilised by OEMs and Tier ones around the globe and provides remote access to engineering teams, no matter where they are based to develop and validate vehicle systems and software. The knowledge and experience gained in this specific field of expertise coupled with HORIBA MIRAs advanced research and consultancy capabilities, we’ve formed a strategic partnership which benefits from each other’s core strengths to deliver a solution for manufacturers and fleets alike which solves one of the biggest upcoming regulatory challenges – lifetime compliance with emerging regulations.