Approach

HORIBA MIRA created an empirical digital twin by running transient cycles on a powertrain dynamometer and measuring the outputs. This data, alongside a virtual representation of the vehicle dynamics, drivability and ADAS systems models, was fed into HORIBA’s proprietary neural network machine learning (ML) algorithm to create a digital twin of the vehicle, combining software in the loop (SIL) and hardware in the loop (HIL) testing.

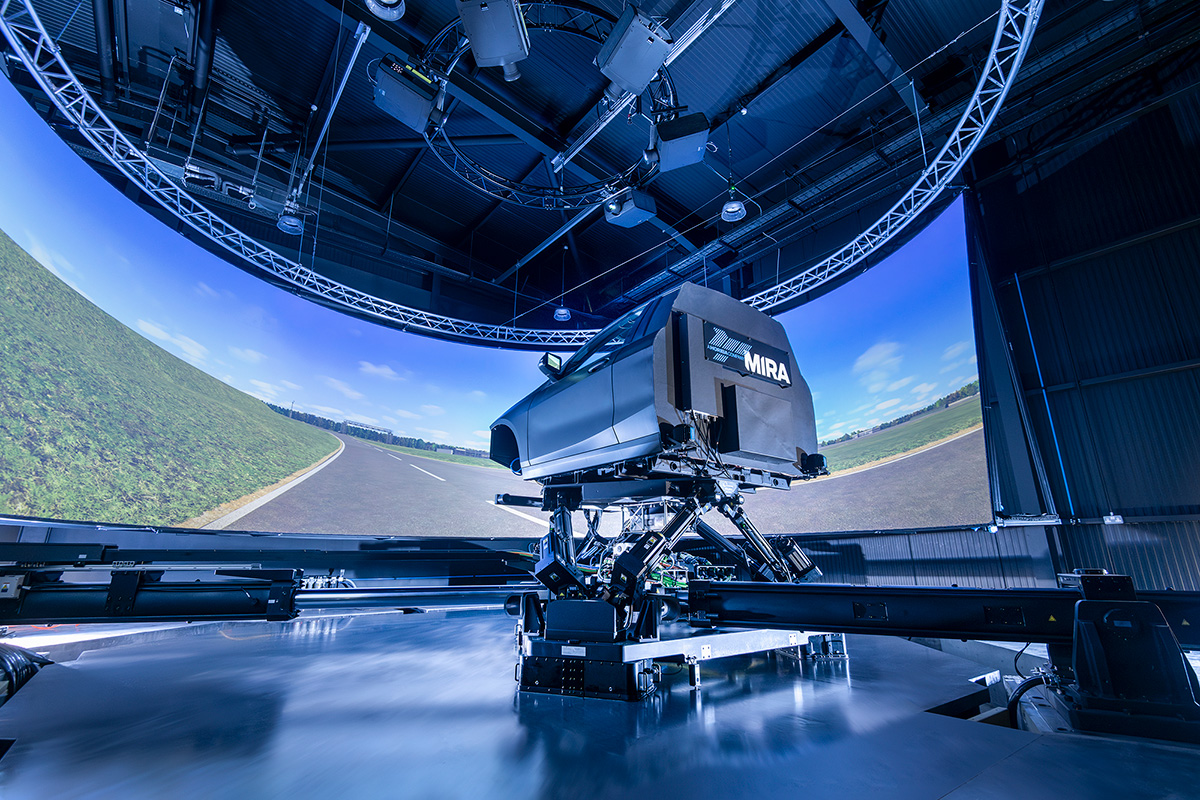

Integrating HORIBA MIRA’s simulator to put a human driver in the loop (DIL) allows a development engineer to provide inputs into the virtual model in a controlled, repeatable environment. Furthermore, it allows a subjective evaluation of the car’s performance, providing the ‘voice of the customer’ during the early stages of a vehicle development programme prior to any physical hardware.

The project’s major success was the real-time linking of the empirical digital twin to the vehicle simulation in the Powertrain Test and Development Centre (PTDC). Running them in parallel enabled co-development of the two attributes, delivering the capability to study real-world scenarios in seconds. HORIBA MIRA’s empirical approach is vehicle agnostic and does not require the vehicle manufacturer to share any sensitive IP. Although

Successes and benefits

HORIBA MIRA’s ViVID work led to the creation of a multi-faceted real-time simulation environment. Notable successes include:

- Establishing a vehicle-agnostic approach for objective and subjective evaluation, with an end-to-end methodology that’s not reliant on existing models. This has allowed HORIBA MIRA to develop new working practices that allow early attribute target setting without the need for the target vehicle to be available

- New process for HIL testing: driving simulator was remotely connected to produce user demands on a physical powertrain in HORIBA MIRA’s Propulsion Development Centre, establishing

a closed loop, real-time feedback ability to inform both powertrain and attribute performance

- Remote connection of the powertrain HIL to the driver simulator was over a kilometre of LAN connection

- Modelling a complex hybrid powertrain for RDE emissions development and drivability evaluations, with authentic human inputs was possible simultaneously in the development

- Introduced ADAS functionality for subjective analysis to enhance consumer acceptance and shorten time to market allowed the human element of driver feel to be assessed early on. Correlation testing validated the simulation against real world performance

- Integrated virtual and physical ADAS scenario evaluation plan, utilising SOTIF principles for efficient testing based on system behavioural competencies and its operational design domain

By combining a digital model with a driving simulator, we were able to link objective data with subjective impressions. This allowed us to really understand the end user experience, which helped to guide our engineering development before any physical hardware has been created.

Tom Lee, Driven Attributes Manager

HORIBA MIRA