MIRA Develops Suspension Solution That Delivers Supercar Handling With Limousine Isolation

Vehicle dynamicists at engineering and test consultancy MIRA Ltd have developed and patented a unique suspension design that answers a conundrum which has long-faced car designers and manufacturers utilising the traditional double wishbone suspension layout – how to optimise their product for handling and comfort?

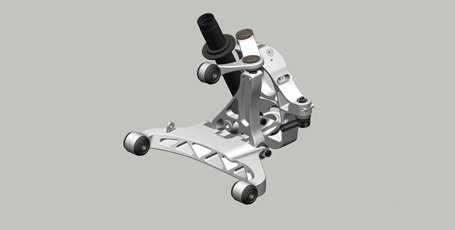

MIRA’s reputation for identifying and finding smart solutions to problems saw a team of engineers deployed on an internal project to develop a revolutionary design that would allow the optimisation of both – and the resulting Interlinked Double Wishbone Suspension (IDWS) design achieves this in a unique way.

Vehicle dynamics engineer Ian Willows, who headed the IDWS project team, commented:

“The continuing trend towards larger wheels and ever lower profile tyres has compounded the problems facing car manufacturers who now need to achieve more suspension isolation for comfort whilst still retaining good wheel control for responsive handling and steering.

Until now there has generally been a need to compromise. A point is reached at which either responsive handling or good isolation is determined to be the dominant concern and then begins the challenge of packaging the appropriate solution within the vehicle’s architecture.”

Until now there has generally been a need to compromise. A point is reached at which either responsive handling or good isolation is determined to be the dominant concern and then begins the challenge of packaging the appropriate solution within the vehicle’s architecture.”

The IDWS overcomes this compromise by effectively decoupling the castor and longitudinal stiffness’s of the traditional double wishbone suspension – creating a solution that delivers the cornering, handling and steering performance of a double wishbone design but with the longitudinal isolation associated with a MacPherson strut arrangement (without its need for height and associated high wing/bonnet lines).

Being both less complex and far more compact than the multi-link arrangements currently in widespread use to achieve similar results, means that the IDWS design can be exploited not only for its combination of dynamic performance and isolation but also by stylists seeking better packaging solutions for lower sleeker lines and pedestrian impact performance criteria.

Having been designed and modelled with the use of CAE, the IDWS design was then prototyped on a premium brand performance car that was originally fitted with a traditional double wishbone suspension, and tested on MIRA’s Suspension Kinematic & Compliance Facility before being put through its paces on the test track.

Ian Willows added:

“The physical performance of the IDWS confirmed the CAE predictions – delivering exceptional steering geometry control, particularly under braking, together with a threefold increase in longitudinal compliance, in comparison to the original standard double wishbone design.”

“The stiffness of the IDWS’ componentry, particularly that of the lower control arm is crucial to its performance. Careful optimisation of the component geometry and material specification is required to realise the full potential of the design. Selection of bush stiffness ratios then allows independent control of the steering geometry and isolation performance to deliver the characteristics desired by the manufacturer.”

As to when the IDWS will go into production, MIRA is inviting discussion with manufacturers interested in either licencing the design or purchasing the patented concept outright.

Pending the outcome of negotiations, the IDWS is likely to be adopted as value added technology for premium vehicle models initially before filtering down to higher volume products.