Approach

The traditional approach to integrating a new powertrain would be to build a proof-of-concept vehicle. Waiting for such a prototype vehicle to be designed, built, made-safe, and finally become available is a time consuming and expensive exercise. Debugging vehicle characteristics or issues on a proving ground / dyno adds to this burden. HORIBA MIRA therefore proposed using an XiL approach in combination with physical testing.

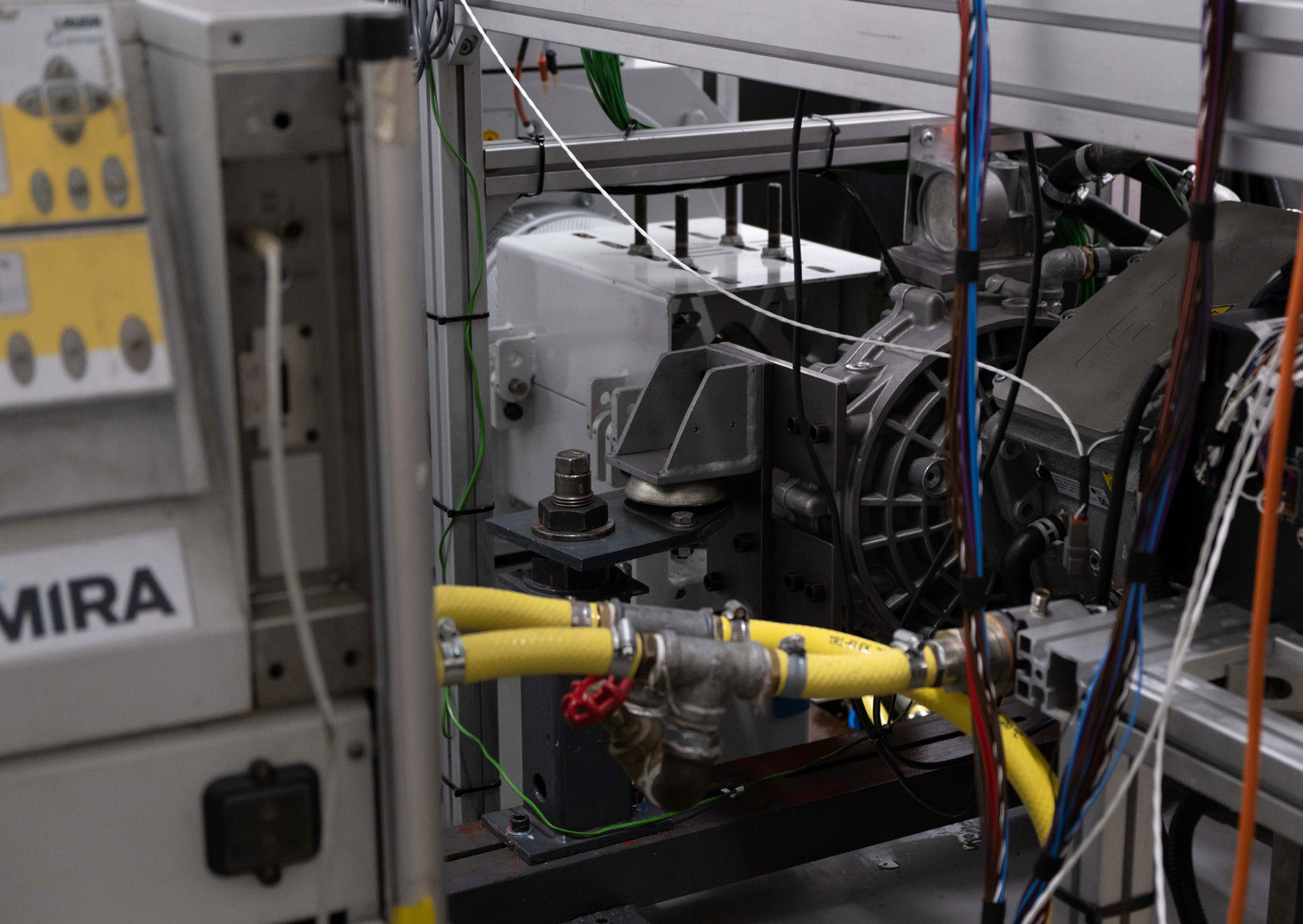

A complete Tevva powertrain was assembled in HORIBA MIRA’s Propulsion Test and Development Centre (PTDC) in Nuneaton. The setup included physical battery packs, thermal emulation, charging system and a motor / invertor /gearbox linked to a 1e Dyno. This was then combined with HORIBA MIRA’s own vehicle simulation model of the Tevva truck.

The combination of hardware and model in the loop provided a complete digital sandbox that could be used for shake-down testing, fault-finding, and initial calibration. This provided the Tevva team with confidence and peace of mind well in advance of having systems running on the proving ground.

Successes and benefits

By leveraging a highly-efficient, simulation-led engineering approach, HORIBA MIRA was able to slash the time and risk involved in Tevva’s new powertrain integration. Highlights of the project included:

- Implementing a whole-vehicle simulation model with a complete powertrain, including both hardware, software, and modelling elements, in a closed loop

- Providing a totally controlled environment for repeatable testing and debugging

- Flexibility to bring in subject matter experts and test services as required, and then step back to provide a more cost-effective long-term solution

- Fast-track approach, enabling the vehicle to be delivered in a heavily compressed time scale compared to traditional methods

HORIBA MIRA has a vast array of engineering competencies in one place, which we can combine to make projects like this as low-risk as possible. There’s nowhere else in the world that gives access to the same spectrum of expertise in one place.

Ben Gale. Solution Leader for Automotive Energy Efficiency

HORIBA MIRA